Shenzhen Sendima Technology Co., Ltd.

Main Products: Plasict machine part, Sushi Mold, Engineering Plastics product, CNC milling machining, Plasict sheet

Home > Company Introduction

Company Overview

Shenzhen Sendima Technology Co., Ltd. is a professional production of engineering plastics, set production, sales, design and processing for the integrated enterprise. The company has a complete set of imported production equipment and a full set of advanced CNC machining equipment, advanced processing methods, strong technical force. Since its inception, the company's own research and development of various rubber products have been known for many domestic machinery and equipment manufacturers and end users, a large number of applications to replace similar imported products. In addition, the products are also exported to Europe, America, Southeast Asia, Middle East, Africa and Taiwan, Hong Kong and other countries and regions, by domestic and foreign customers alike.

Advanced production and processing methods

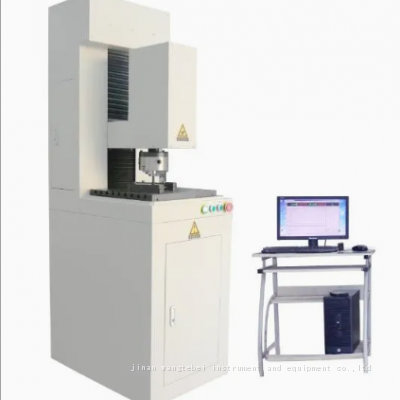

Machining

Sendma Co.,LTD. equipped with the latest AutoCAD software, and connect with CNC machining centers, customer's specific requirements to provide a full set of services, including product design stage of the profiles selected to material specifications determined until the final product production and processing. Skilled workers in the operation, advanced processing equipment, perfect detection means, from raw material procurement to products production process are strictly controlled all aspects for product quality to provide a strong guarantee.

Injection molding and mold design

We Own mold development, design and manufacturing, experienced professional and technical personnel color, from product mold manufacturing, to test mode, repair mode, and then injection molding and casting products, our company can provide one-stop service, greatly reducing the product injection molding and casting production cycle. The company has advanced EDM, wire cutting and other specialized equipment, and mastered the injection molds and casting molds unique manufacturing technology, excellence in the design and quality of the products, so Sendima Technology Group Limited molds reputation far Young customers throughout the north and south.

In addition, for outlet material and machining scrap, we also specialized recycling company to achieve economical, environmental requirements.

-

Manufacturer, Trading CompanyBusiness Type

-

2012Year Established

-

1,000-3,000 square metersFactory Size

-

51 - 100 PeopleTotal Employees

Company Detail

Transparency is the foundation of our partnership. Below is a comprehensive overview of our operational metrics, from business scale to global market reach, giving you a clear picture of our capabilities.

-

51 - 100 People Total Employees

-

Domestic Market, Central America, North America, Western Europe, Eastern Europe, South America, Northern Europe, Mid East, Southeast Asia, Africa Main Markets

-

Shenzhen, Guangzhou, Hongkong Port of Shipment

-

Plastic Rod Main Industry